| CNC Machining or Not | Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

| Place of Origin | Shandong, China |

| Type | Broaching, DRILLING, Laser Machining, Milling, Other Machining Services, Turning |

| Micro Machining or Not | Micro Machining |

| Model Number | CUSTOMIZED |

| Brand Name | tianfengde |

| Material | Customized |

| Process | Cnc Machining+deburrs |

| Product name | Machining Parts |

| Surface treatment | Customer’s Request |

| Application | Industrial Equipment |

| Equipment | Three Axis CNC Machining Center |

| Keyword | Processing Parts |

| Color | Customized Color |

| Size | Customized Size |

| MOQ | 50pcs |

| Packaging Details | in bundles,water proof plastic packing, in bulk etc . |

| Port | Qingdao |

Supply Ability

Product Description

| Main Product | CNC machining parts, Precision mechanical components, Precision milling parts |

| Surface Treatment | Zinc plating,Nickel plating,chromate plating,anodize as per customer’s requirement |

| Quality control | 1) Material quality inspection |

| 2) Precision inspection | |

| 3) Appearance inspection | |

| 4) Functional quality inspection | |

| 5) Structural quality inspection | |

| 6) Surface treatment quality inspection | |

| 7) Packaging quality inspection | |

| Production Equipment | 1)CNC Machining Center; |

| 2)CNC Lathe; | |

| 3)CNC Milling Machine; | |

| 4)Precision Cutting Machine | |

| Measuring Instruments and Equipment | 1)micrometer, |

| 2)smooth plug gauge, | |

| 3)thread gauge, | |

| 4) Image measuring instrument , | |

| 5) Coordinate Measuring Machine , | |

| 6) Roughness tester , | |

| 7) routine inspection of calipers | |

| Preferred Drawing Formats | JPEG, PDF,CAD,IGS,STP |

| Preferred Industries | 1) Communication Equipments |

| 2) Medical Equipments | |

| 3) Photoelectricity Equipments | |

| 4) Auto Industry | |

| 5) Mechanical Equipments | |

| 6) Other customized Parts |

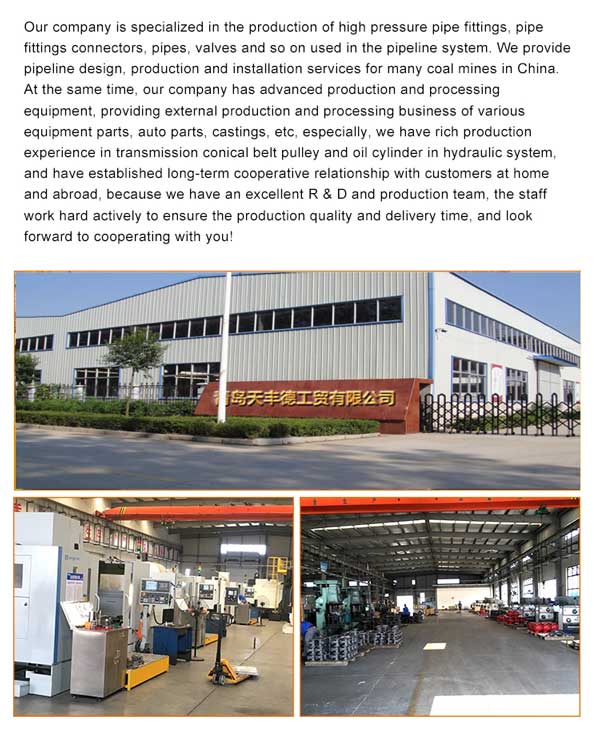

Company Information

Why choose us

1. We are a physical factory, not a trading company. The quality is easier to control, the price is lower, and the service fee of the trading company is reduced.

2. Design service: We play an active role in the early stage of customer product design and development cycle, providing customers with value-added design solutions and specific suggestions to solve specific design and technical problems

3. Selection of raw materials: We integrate all raw material needs and purchase large quantities from approved suppliers with reasonable cost and high quality, which reduces customer costs.

4. Poduction and inspection: We use sophisticated processing and manufacturing equipment (processing centers, CNC lathes, drilling machines, etc.) to complete the manufacturing services of customers’ highly complex precision metal products. At the same time, our testing equipment includes automatic three-coordinate testing machine, pressure test bench, hardness tester, vernier caliper, etc.

5. About customization: Our engineers are proficient in AUTO CAD, PRO ENGINEER, SOLID WORKS, UG and other 2D and 3D software. We can design, develop, produce and deliver according to customer requirements.

FAQ

Q1. Can I have a sample order ?

A: Yes, we welcome sample order to test and check quality.Mixed samples are acceptable.

Q2. Do you have any MOQ limit order?

A: Low MOQ, 1pc for sample checking is available

Q3. How do you ship the goods and how long does it take to arrive?

A: We usually ship by sea. It usually takes 30 days to arrive. Airline shipping also optional.

Q4. How to proceed an order ?

A: Firstly let us know your requirements or application. Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q5: Are you products standard?

A: Our model is standard, if you have specific demand, pls tell us.

Q6: Do you have interest to do our own design items?

A: Absolutely! We have big interest.